Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

36.4440

Euro

38.2599

Saudi Riyal

9.7318

Pound Sterling

46.1616

Kuwaiti Dinar

118.3468

United Arab Emirates Dirham

9.9230

Egyptian Pound

0.7197

Iraqi Dinar

0.0278

Bahraini Dinar

96.6992

Qatari Riyal

10.0154

Libyan Dinar

7.4451

Omani Rial

94.6573

Jordanian Dinar

51.3658

Algerian Dinar

0.2699

Moroccan Dirham

3.6642

Syrian Pound

0.0028

Grape Molasses Production Line

710,658 TL

Gaziantep / Şehitkamil

Status

New

Advertiser

Manufacturer

Year

2024

Details

Address

Gaziantep / Şehitkamil / Sanayi mah.

Offer number

00378672

Offer date

2024/05/17

Communication Languages

Grape Molasses Production Line

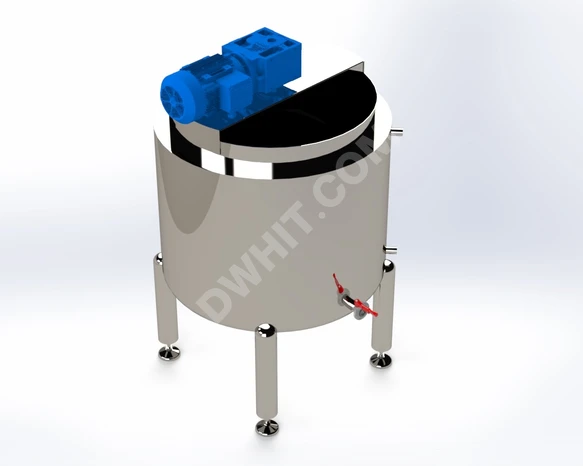

Industrial grape molasses cooking equipment

The industrial grape molasses cooking system consists of the following main components:

1. Chrome tank:

- Made of high quality stainless steel.

- Tank capacity ranges from 400 liters to 500 liters.

- Equipped with an airtight lid to prevent air from entering.

- Equipped with a ventilation fan to prevent water vapor accumulation.

- The tank is heated using a direct heat source.

- The direct heat source is a gas stove or oil burner.

- The indirect heat source is often a steam boiler or hot water heating system.

2. Cooling tank: - Made of high quality double jacketed stainless steel.

- The cooling tank capacity ranges from 400 liters to 500 liters.

- Equipped with a cooler to ensure rapid and effective cooling of the grape molasses.

- Water chiller or air chiller is used to cool the cooling tank.

- Equipped with a drain valve to drain the grape molasses from the tank.

Additional components:

Pump: To transfer grape molasses from a cooking tank to a cooling tank.

Filter: To filter grape molasses from impurities.

Control panel: to control cooking temperature and cooling speed.

Valves: to control the flow of grape molasses.

Pipes and valves: to connect grape molasses between different components.

Features of industrial grape molasses cooking equipment:

Ease of use and cleaning.

High efficiency in cooking and cooling.

High quality grape molasses.

Adjustability to meet different production needs.

Applications:

- Industrial grape molasses cooking equipment is used in the food industry to produce grape molasses in large quantities.

- They can also be used in other industrial applications, such as juice and sugar production.

Similar offers

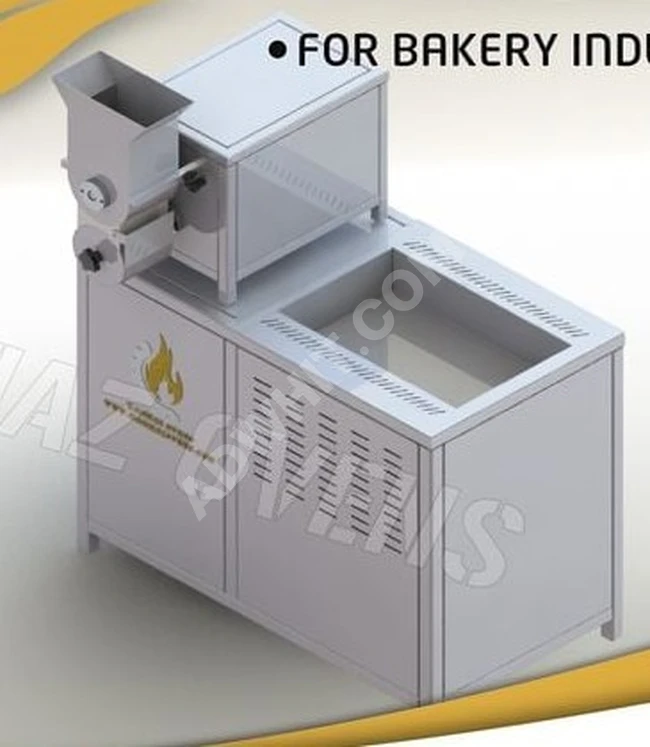

Wafer Machine

40,000,000

TL

New

Manufacturer

Selçuklu, Konya

2025/02/22

Date Sorting Line

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/24

Date Molasses Production and Packaging Line

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/18

Arabic bread production line

65,000

TL

New

Manufacturer

Merkez, Kilis

2025/01/20

Petit Four Machine

0

TL

New

Manufacturer

Merkez, Kilis

2025/01/24

Falafel manufacturing machine

1,000

TL

New

Manufacturer

Merkez, Kilis

2025/02/04