Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

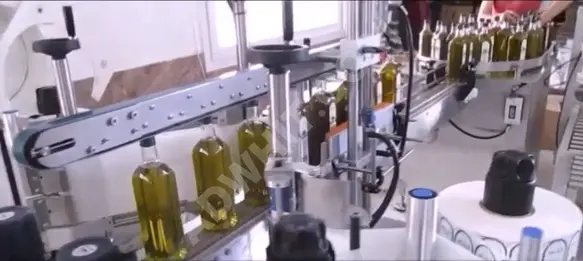

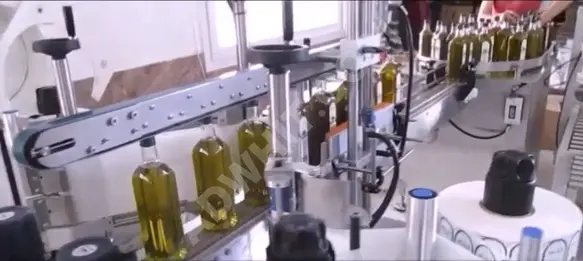

Double-sided labeling machine

Double-sided labeling machine

Model type: FGM OÇTE 002

Designed for those looking for an ideal labeling solution, the two-way labeling machine is a reliable choice for increasing productivity and improving workflow. This special machine performs high-quality labeling operations quickly and accurately.

Double-sided labeling: Promote your product in the most effective way by being able to place labels on both the front and back surfaces.

High precision: Thanks to advanced sensor technology, labeling operations are carried out with perfect precision.

Fast Labeling: Optimize your production processes with automation features and a fast labeling mechanism.

Ease of Use: It can be easily used by employees of all levels thanks to its user-friendly interface and simple control panel.

Flexible Compatibility: It can work with labels of different sizes, meeting diverse industrial needs.

Applications:

Food and beverage industry

Beauty and personal care products

Medicines and medical devices

Logistics and warehousing

Auto industry

Other industrial applications

This two-way labeling machine is an ideal solution to meet your business's labeling needs and increase productivity. Thanks to their high performance and durability, they are manufactured to industry standards and have operated reliably for many years.

Technical Specifications:

Pulley diameter: 75mm

Label width: 10-240mm

Label length: 10-300mm

Label exit speed: 5-15m/min

Number of labels: 3000-4000pcs/hour

Control system: PLC control

Unit: 2 HERMA 240V units

Operating voltage: 220V 50Hz 12A

Control voltage: 24V DC

Label sensors: Possibility of working with transparent and opaque

Start label: Reflective optical sensors of the body

Bottle winding belt: 0.18 kw x 30 t 15

Upper printing belt: 0.18 kW x 30 T 15

Bottle correction belt: 3 PH 12.5 B

Bottle separator motor: 0.18 kw x 30 i 60

Construction: High quality 304 stainless steel

Conveyor and winding motor: 380V 0.37kW (S40/21)

Energy consumption: 1 kW/h

Our labeling machine is complete and the bottles are separated on the conveyor by bottle separator motor leaving a gap. There is a wrap belt for round bottles to completely wrap around them. For square and corner bottles, there are two bottle correction belts and one upper printing belt for marking on both sides.