Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

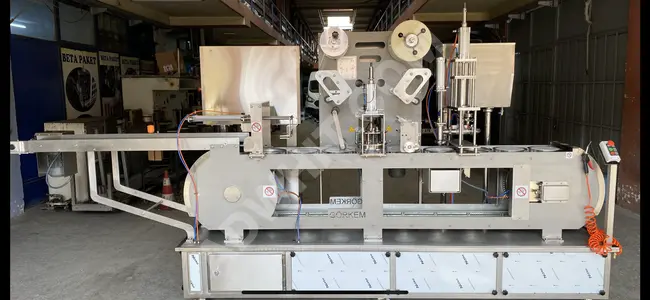

Water, ayran, and yogurt filling machine with 6 tracks

Water, Ayran, and Yogurt Filling and Sealing Machine with a Production Line Consisting of 6 Lanes

Materials Used: The machine is entirely made of stainless steel with 304 quality, including the gear and chain framework.

Production Capacity: The production capacity reaches up to 8,500 packages/hour for packages with a capacity of 200 grams.

Control System: The machine is controlled using a Panasonic PLC controller.

Control Screen: The color touch screen facilitates the machine control process.

Lanes Management: The machine consists of 6 lanes, each of which can be independently controlled, allowing easy intervention in desired stations for any lane. The machine includes filling sensors, cap placement sensors, suction generators, and valves, all working independently for each lane without sharing.

Fault Diagnosis: Electrical signals can be monitored through the color screen to simplify the process of detecting any potential electrical faults.

The screen allows for conducting tests for the pneumatic system and easily verifying and monitoring the performance of pneumatic stations.

Thanks to the presence of a speed control system (Inverter), the operator can adjust the operating speed according to their needs.

The filling system relies on free flow (gravity filling) using the weight of the material.