Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Aluminum Foil Plate Machine

Aluminum Foil Plate Machine

Nominal Force

800KN

Main Engine

18.5KW, SIEMENS

Stroke Range

150-260mm

Adjustable Speed 35-80 times/min.

Number of Adjustable Pressure Solenoid Value Connections

12 teams (2*6 cities)

Bearing Plate Size

L1480xW900mm, 2 sets of moving plates

Maximum Mold Size

L1450xW850xH500mm

Number of Air Tanks

6 units

Press Lubricant Solution

Liquid Hydraulic Oil, Automatic Cycle

Max. Foil Passage Width

1220mm

Feeder Tension Control

Automatic with Ultrasonic Sensor

Maximum Diameter of Foil Roll

600-1500mm

Feeder Sensitivity Control

±0.1 mm, Mitsubishi Servo System

Stacker Belt Size

L2000xW1300mm

Min.Size Stack Available

100x100mm

Products Stacking Size Three-lane: L600xW350xH350mm Four-lane: L600xW250xH350mm

Five lanes: L600xW210xH350mm Six lanes: L600xW170xH350mm

Lifting System SMC Servo Cylinder

Main Electrical Brand

Mitsubishi,SMC,Schneider,OMRON,SIEMENS

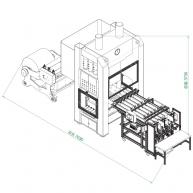

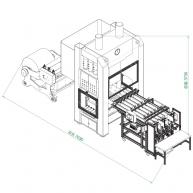

Production Line Size

8000x2500x3650mm

Definition

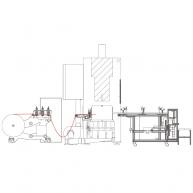

SEAC-80A adopts customized H-Type Octahedral Guide Rail Mechanical Press with higher precision. Mainly use for Crinkle Wall Container production. The software and hardware of the entire production line adopt the beautiful and generous Mechatronics design.

The entire automatic production line mainly consists of Feeder, Press, Stacker and Scrap System units.

The electrical control system of the whole production line is divided into two parts:

The integrated electrical control cabinet, consisting of three units of Feeder, Press and Scrap System, adopts safe and anti-interference independent system design.

The touch screen is hung on the left side of the Press, which is convenient to use and does not take up space;

The stacker's electrical cabinet is mounted on one side of the Stacker to independently control all parameter settings and operation.

The PLC program logic of the entire production line is perfectly matched; This greatly improves the Production Efficiency of the whole machine and the Rationality of the Program Control logic, and is more intelligent humanized.

Advantages

1.Adopts Aluminum Foil Feeding Servo System: Excellent performance for aluminum foil materials with different thickness and large width to complete the feeding quickly and more accurately. Curve output torque makes the aluminum foil stable without shaking.

2. Press Adopted Automatic Circulation Lubrication System: The progressive lubricating oil distributor is equipped with Lubrication Failure Detection Switch to ensure sufficient and uniform lubrication, avoid damaging the guide rail during oil-free operation.

3. Highly Precise and Reliable Italian OMPI Dry Clutch and Japanese TACO Double Solenoid Valve are adopted to ensure the accuracy and safety of timely stopping of the sliding block of the press.