Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

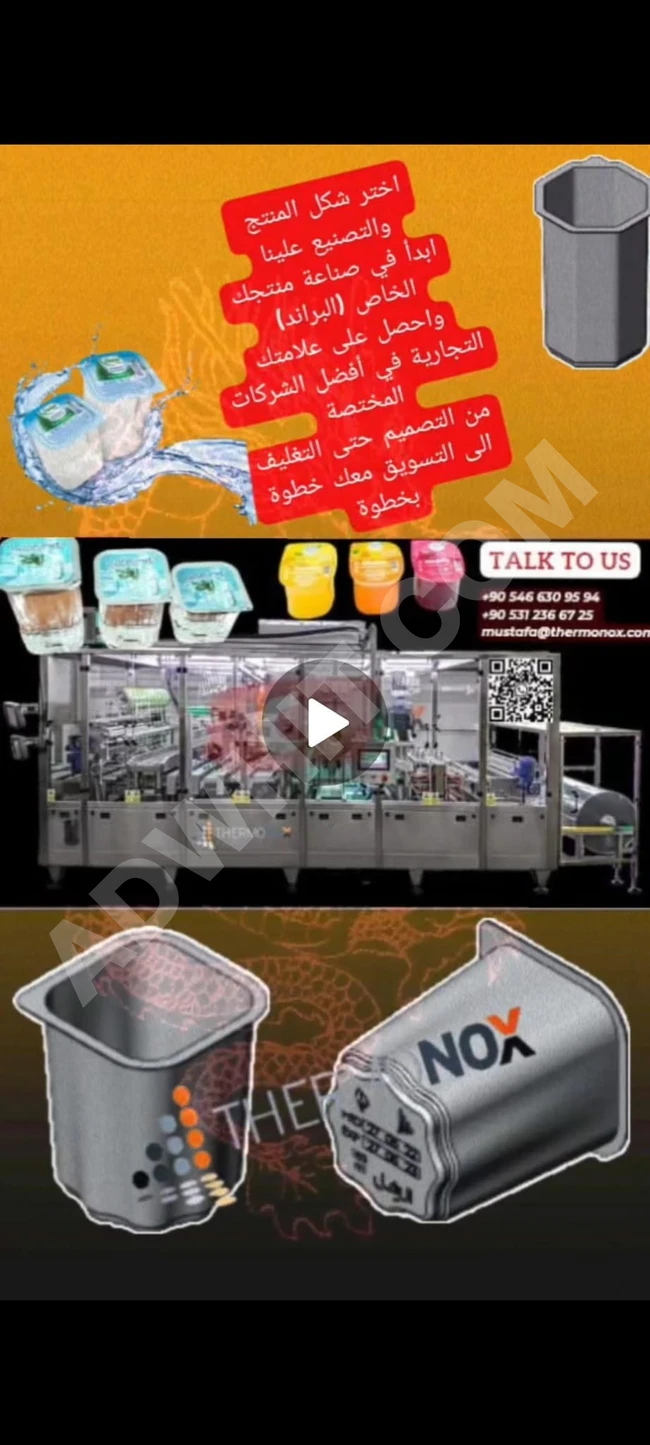

Automatic machine for filling gel and cream

Gel and cream filling machines are important equipment used in the cosmetics and food industry. These machines are designed to precisely fill high density liquids such as gel, cream, sauce, and jam. Their functions and features vary from one manufacturer to another, but they usually contain the following features:

Dosage Control: These machines provide precise dosage control for high viscosity products, ensuring that products are packed in precise quantities. This ensures that the products are packed perfectly.

Automation: Thanks to automation features, the packaging process becomes more efficient. These machines can usually perform filling, sealing, and labeling operations automatically.

Hygiene standards: Like any equipment used in the food industry, gel and cream filling machines must be clean. Manufactured from healthy materials such as stainless steel, makes cleaning easy and prevents contamination of the products.

Diverse packing options: Provides packing options suitable for different types of products. For example, it can have interchangeable nozzles or different filling methods for filling liquids of different viscosities.

Easy to adjust: Adjustment feature according to product type and packing size allows users to adjust the machine to meet different needs.

These machines speed up production processes in the cosmetics and food industry, improve product quality and maintain hygiene standards. It is used in filling, closing, and labeling operations on products such as gel and cream according to the needs of the manufacturers and the characteristics of their products.

Technical Specifications :

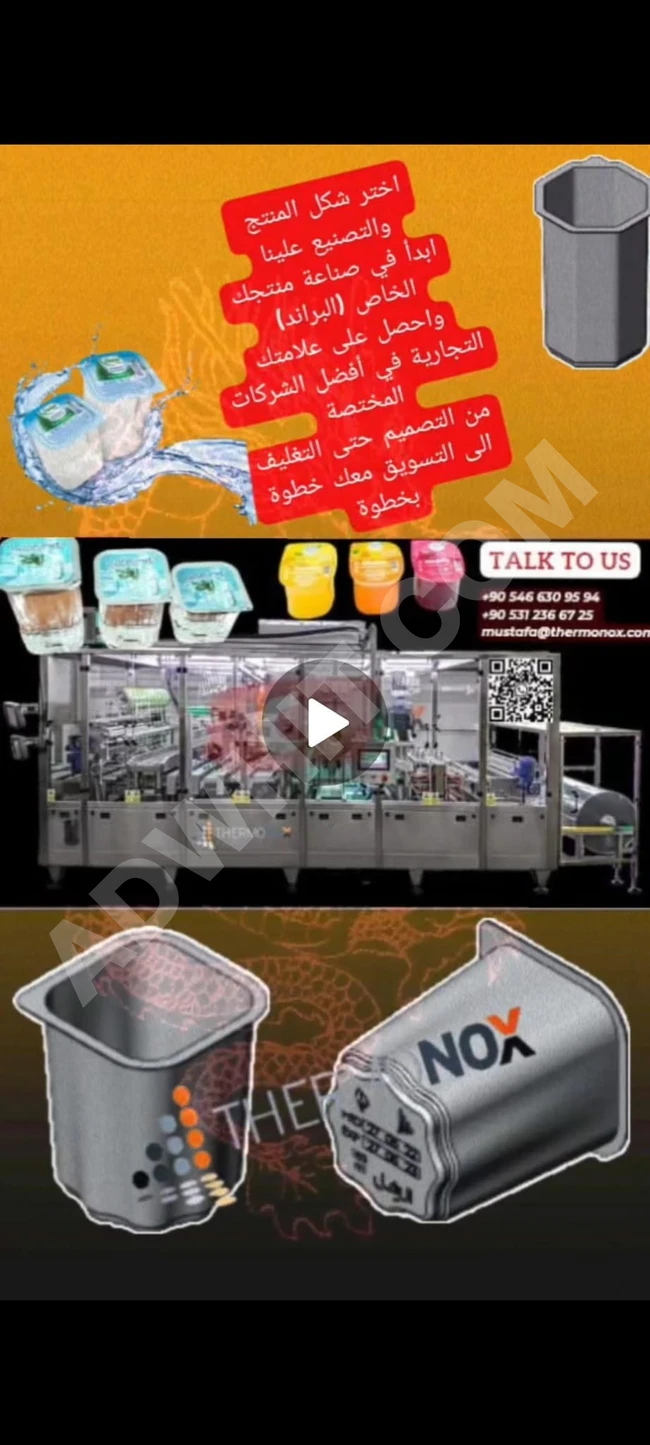

Gel and cream filling machine

Packing set: 304 quality stainless steel

Sealing elements: PTFE TEFLON and VITON

Control systems: Touch screen and electro-pneumatic system (LG PLC and LG 7 inch touch screen + Pemaks pneumatic system) Language options: Turkish and English

Blocker: Nozzle system (2 heads) is custom made.

Filling system: Pemaks pneumatic system

Packing size: 500 ml

Filling capacity: 1000 units/hour

Control voltage: 24V DC

Operating voltage: 380V 50Hz 10A

Energy consumption: 1 kW/h

Dimensions: H 2200mm x 1000 x 1000 x 3000mm

Conveyor: (3 meters of acetal pallet)

Protection chambers: Plexiglas coating on 304 quality body (for filling and sealing)

Cap Closing Machine (Screw Cap Closing)

Body: 304 quality stainless steel

Conveyor pallet: (3 meters of acetal pallet)

Conveyor motor: 380V 0.37kW (S40/21)

Energy consumption: 1 kW/h

Closing the covers: Close the covers with torque screws

Dimensions: H 1800mm x 1000 x 1000 x 3000mm