Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

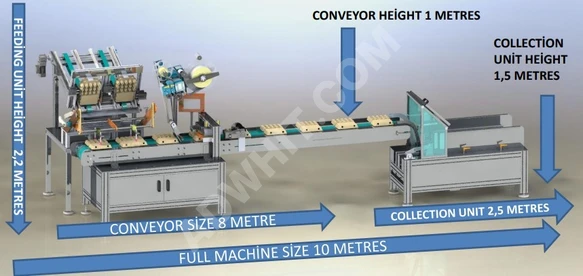

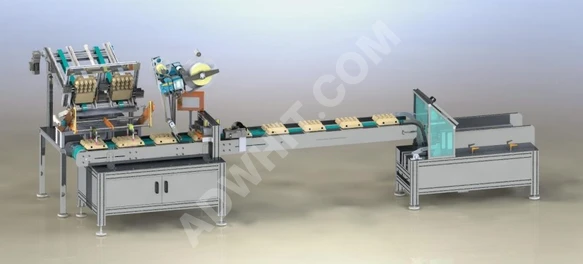

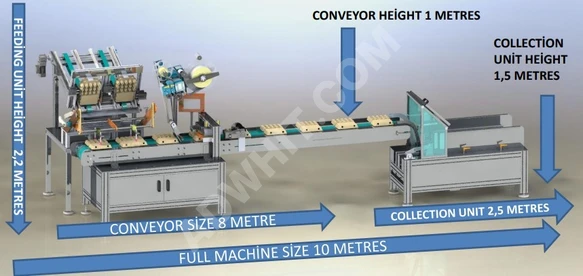

Violl Egg Labeling Tool

Feeder weight: 350 kg

Conveyor units weight: 850 kg

Assembly units weight: 300 kg

Gross weight: 1500 kg

product specification:

- High speed, high capacity.

- The capacity of one machine reaches 60 units or 90 units per minute.

- It is driven by a servo motor, characterized by speed, accuracy and wide applicability.

- Triple servo system: feeding system, collecting system, and the entire conveyor chain system.

- Placing labels at a speed of 50 meters/min.

- Power supply: 220V/50Hz/5.5kW (can be adjusted according to countries voltage).

- 8 pneumatic pistons (the machine needs 6 pistons) - 8 air pistons.

- 6 vacuum injections for vacuum holders (needs a minimum 1000 liter air tank).

- Italian-made Etipack label applicator with speed of 50 m/min.

- 10-inch Delta touch screen.

- PLC Delta.

- Electrical materials from Schneider Electric.

- SICK sensors.

- Servo driven indicator conveyor.

- Pneumatic cylinder drive for labelers and carton setters.

-Quick-change mechanisms for magazines and unloaded body for quick and frequent changes

- Two DVP vacuum pumps; One for the covers and one for the stickers.

-Double or triple bar top stack with cross push discharge.

- Adjustable wheels and feet for movement.

- OMRON operator interface.

- Double-strip machine - 60 label cartons per minute.

- Three-strip machine - 90 cartons per minute.

- 12 double-layer egg cartons, 18 or 24 double-layer egg cartons.

- 460/230 volts, multi-voltage, three-phase (may vary by country).

- 60Hz, separate drop system for main machine and glue.

-Control voltage: 24V DC.

- 80 PSI clean/dry air - 6 - 8 bar